Small-Scale Reverse Osmosis (RO) Equipment

All Products

Want More Information ?

More Wastewater Solution ?

Product Profile

EcoLan small-scale reverse osmosis water treatment equipment can meet the demand for pure water with relatively small water consumption. Like the large-scale reverse osmosis system, it is a water treatment system composed around the reverse osmosis membrane, including the pretreatment part, the reverse osmosis membrane filtration part, the post-treatment part, and the system cleaning part. However, it mainly uses the reverse osmosis membrane to retain inorganic salt ions such as calcium and magnesium ions in water and reduce the conductivity of raw water to below 10μs/cm to meet the standard for production usage, ensuring the safety and stability of pure water.

Product Features

PLC Programmable Intelligent Control System and Human-Machine Interface Operating System

It has LCD liquid crystal display, man-machine dialogue, clock, and language setting function. After the start-up, the electronic control system of the equipment automatically detects and puts in the chemicals automatically and proportionally, fully automatic treatment of raw water and preparation of pure water.

Online Water Quality Detection and Control to Ensure Water Quality Meets Requirements

Equipped with high-quality product water and concentrated water flow meter, raw water and product water conductivity meter, and pH meter for real-time detection of water quality and system water yield and recovery rate to ensure the regular operation of the reverse osmosis system and the production of pure water to meet the requirements.

Automatic Flushing Function and Advanced Membrane Protection System

Configure chemical cleaning system, inlet water, and drainage pressure gauge, continuously monitoring the pressure difference of reverse osmosis membrane, prompting timely cleaning and automatic flushing. Built-in advanced membrane protection system, when the equipment turns off, it can automatically flush the dirt on the membrane surface with product water to prolong the service life of the reverse osmosis membrane.

Small Size of Equipment, Simple Installation and Maintenance, Unattended

Compact design, small footprint, easy operation, fully automatic operation, low operating cost, can be used unattended.

Pretreatment Equipment Tank Material Optional

Under the same configuration, customers can flexibly select FRP and stainless steel tank material. Compared with FRP, stainless steel can withstand higher temperatures and tremendous pressure, which can meet the higher needs of users.

Product Technical Parameters

| Structure material | Stainless steel | Product type | Reverse osmosis system |

| Feed water pressure | 0.2~0.4MPa | Water hardness | <6m mol/L |

| Iron content in influent | <0.3mg/L | Influent turbidity | <5NTU |

| Manganese content in influent | <0.1mg/L | Feed water temperature | 2~45°C |

| Residual chlorine in influent | <0.1PPM | Voltage | 220V/380V |

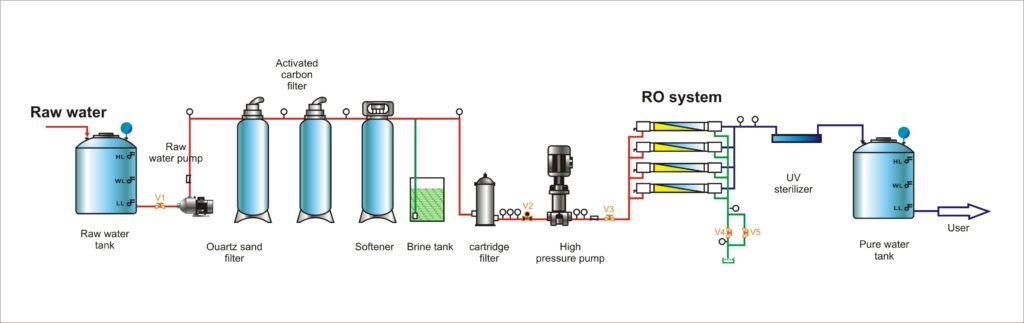

Process Flow Diagram

The raw water (tap water, surface water, groundwater) goes through a pretreatment system and precision filter. Then, the water is sent to the reverse osmosis device through a high-pressure pump to prepare the product water directly. It is a primary reverse osmosis, suitable for the water quality with a conductivity of less than 300μs/cm, and the product water conductivity is less than 10μs/cm. The first-stage reverse osmosis product water can also be filtered by one more reverse osmosis unit, the second-stage reverse osmosis system to meet better effluent conductivity requirements.

Product Specification Selection

| Model number | Production water (T/H) | Motor power (KW) | Recovery rate (%) | Pure water conductivity (μs/cm) | Raw water conductivity (μs/cm) |

| EL-RO-500L | 0.5T | 1.5 | 50% | ≤10μs/cm | ≤300μs/cm |

| EL-RO-1000L | 1T | 2.2 | 50% | ≤10μs/cm | ≤300μs/cm |

| EL-RO-2000L | 2T | 3.0 | 50%~60% | ≤10μs/cm | ≤300μs/cm |

| EL-RO-3000L | 3T | 4.5 | 55%~65% | ≤10μs/cm | ≤300μs/cm |

| EL-RO-4000L | 4T | 6.5 | 55%~65% | ≤10μs/cm | ≤300μs/cm |

| EL-RO-5000L | 5T | 8.0 | 60%~70% | ≤10μs/cm | ≤300μs/cm |

Scope of Applications

Biopharmaceuticals

Chemical industry

Drinking water

Power industry

Electronics industry

Photovoltaic industry

Lithium Industry