Pure & Ultrapure Water Solutions

Pure & Ultrapure Water Solutions

Table of Contents

The traditional preparation process of pure and ultrapure water is usually made by ion exchange resin. Still, the ion exchange resin requires frequent regeneration, which is both costly and labor-intensive. EcoLanTM adopts reverse osmosis technology, or the process combined with EDI to prepare pure water and ultra-pure water, after years of practice and experience, which has the advantages of low operating cost and high operational reliability compared with the traditional process. The reverse osmosis technology is advanced, stable, and reliable, while the EDI technology does not require chemical regeneration, no wastewater discharge, and low operating cost.

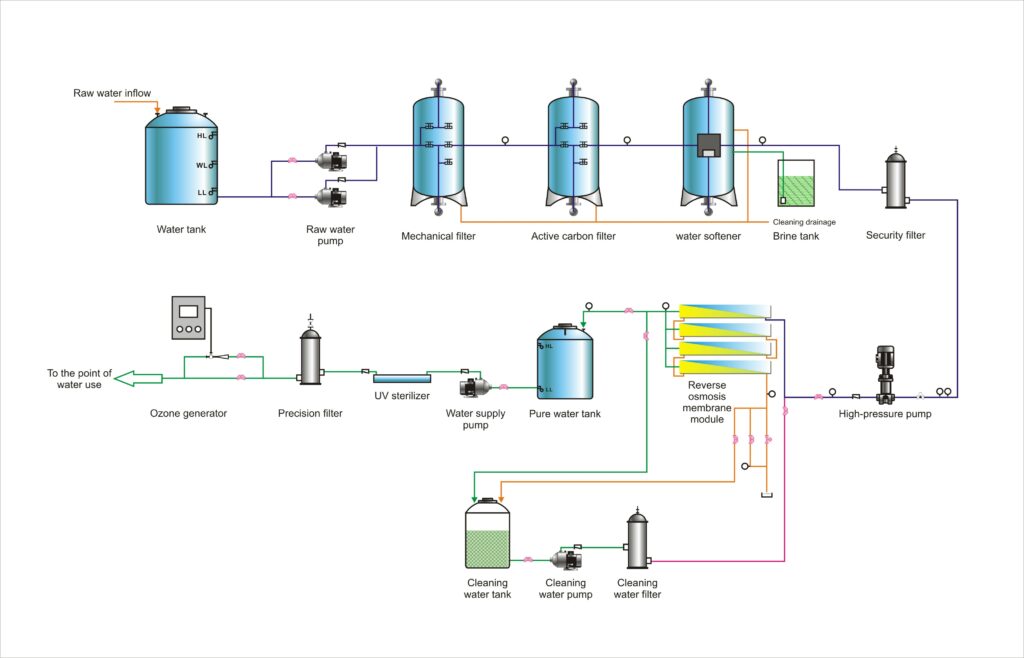

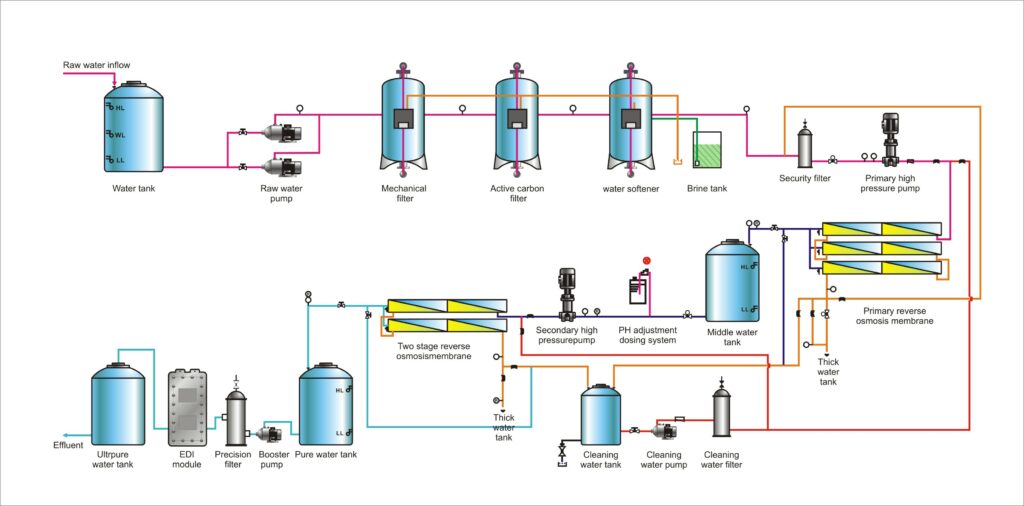

Process flow diagram

1. The pure water preparation process

2. The ultrapure water preparation process

Process flow and description

1. Raw water pretreatment system

Municipal network water supply contains a variety of impurities, such as suspended solids, colloids, organic matter, inorganic salts, etc. Therefore, it is necessary to remove the suspended solids, colloids, and organic matter in the water to make the reverse osmosis feed water meet the requirements and ensure the regular operation of the reverse osmosis desalination part in the system. Therefore, the system sets up the raw water pretreatment system, including the raw water tank, the raw water booster pump, the multi-media filter, and the activated carbon filter.

A. Raw water tank

Used to store the raw water entering the pretreatment system, its purpose is to prevent the inlet water pressure fluctuations from affecting the system’s operation and provide sufficient water storage to meet the filter backwashing needs. The tank comes with a level controller, which controls the automatic water replenishment valve and the start/stop of the raw water pump through the level of the tank.

B. Raw water booster pump

Pumping water from the raw water tank is used to enhance the pressure of the raw water supply to meet the pressure and flow required for the regular operation of the subsequent treatment equipment. The level controller on the raw water tank controls the raw water pump. When the raw water tank is at a low water level, the raw water pump stops delivery to avoid damage caused by working in a waterless state.

C. Automatic multi-media filter

Multi-media filter is the essential equipment of a reverse osmosis pretreatment system; its role is to filter out the fine particles, suspended solids, colloids, and other impurities in the raw water so that the water can be further clarified and purified. After filtration by multi-media filter, the SDI15 value of raw water can reach the requirement of RO feed water conditions that SDI15<4. However, as time goes on, the pressure difference between the front and rear of the filter will rise until it fails. At this time, it is necessary to use the reverse water flow to backwash the filter media to loosen and suspend the filler so that the retention materials adhering to the surface of the filler can be stripped and taken away by the water flow to restore the filtration function. The filter has an automatic electric valve set to automatically realize the switching of filter operation, backwashing, and positive washing stations.

D. Automatically activated carbon filter

The activated carbon filter uses the adsorption characteristics of activated carbon to adsorb organic pollutants, microorganisms, and dissolved oxygen in water on the surface of the carbon. It increases the chance of microorganisms degrading organic pollutants, extending the residence time of organic matter, strengthening biodegradation, removing the organic matter adsorbed on the surface of the carbon, and further improving the water quality of RO feed water. At the same time, it can also remove odor and taste from water, pure color, remove heavy metals, synthetic detergents and dechlorinate, etc. It can effectively prevent organic matter and chlorine pollution on the surface of the RO membrane. Likewise, the filter comes with an automatic electric valve set to automatically realize the switching of filter operation, backwashing, and positive washing stations.

E. Softening dosing device

Reverse osmosis scale inhibitor and dispersant is a high-efficiency liquid scale inhibitor used to control scale deposits in membrane separation systems and effectively control the scale of calcium carbonate, calcium silicate, and calcium sulfate. It has significant scale inhibition efficiency and does not form an insoluble polymer with a residual organic coagulant. Therefore, it is essential for reverse osmosis (RO), nanofiltration (NF), or ultrafiltration (UF) systems without ion exchange pretreatment to prevent scaling, improve water production and quality, and reduce operating costs.

2. Reverse osmosis pre-desalination system

A reverse osmosis pre-desalination system is a critical step in pure and ultra-pure water preparation, mainly including the following parts.

A. 5µm security filter

The filter removes particles and impurities more significant than 5µm that the pretreatment process may bring to prevent them from entering the reverse osmosis system. These particles may penetrate the reverse osmosis membrane modules after passing through the high-pressure pump of the reverse osmosis, thus causing a large amount of salt leakage and water cascading phenomenon. It also affects the effluent quality and may scratch the impeller of the high-pressure pump. The filter element of the security filter is a replaceable melt-blown filter element. When the differential pressure between the inlet and outlet of the filter is greater than the set value (usually 0.07~0.1MPa), the operator should replace the filter element.

B. High-pressure pump

The role of the high-pressure pump is to raise the pressure of the RO water inlet, to meet the pressure and flow of the water inlet required for the operation of the RO device, and to ensure the regular operation of the reverse osmosis membrane. The first-stage high-pressure pump is linked with the raw water pump, and when the raw water pump stops due to water shortage, the first-stage high-pressure pump also stops simultaneously. The first-stage high-pressure pump is linked to the multi-way valve. The first-stage high-pressure pump will stop automatically when the multi-way valve changes from filtration to flushing or regeneration. The first-stage high-pressure pump is also controlled by the liquid level of the first-stage RO water production tank; when the first-stage RO water production tank is full, the first-stage high-pressure pump stops. The secondary high-pressure pump is controlled by the level of the secondary RO water production tank, and the second high-pressure pump stops when the secondary RO water production tank is full.

C. Reverse osmosis plant

Reverse osmosis technology is a membrane separation and filtration technology powered by pressure difference; its pore size is as tiny as a nanometer (1 nanometer = 10-9 meters), and under a certain pressure, H2O molecules can pass through the RO membrane. In contrast, raw water’s inorganic salts, heavy metal ions, organic matter, colloids, bacteria, viruses, and other impurities cannot pass through the RO membrane. Thus it makes a strict distinction between pure water that can pass through and concentrated water that cannot. The RO unit mainly consists of a high-pressure pump, a membrane shell (pressure vessel), a reverse osmosis membrane, and a control system. The high-pressure pump pressurizes the inlet water. Except for water molecules that can pass through the RO membrane, almost all other substances in the water (minerals, organics, microorganisms, etc.) are rejected outside the membrane. As a result, these substances cannot pass through the RO membrane, washed away by high-pressure concentrated water. Furthermore, the reverse osmosis device set up enough online instruments to visually reflect the device’s operation status, such as a pressure gauge, flow meter, conductivity, etc., which will ensure the device’s long-term quality and quantity of operation.

D. PH adjustment device

The reverse osmosis membrane has no retention effect on CO2, which generally needs to be removed after passing through the first-stage reverse osmosis to improve the conductivity of the second reverse osmosis effluent. In the process, CO2 is converted into HCO3- and CO3 2- by adding NaOH, while reverse osmosis has a high removal rate of HCO3- and CO3 2-. the pH-adding system is controlled in a fully automatic way, equipped with a metering pump to add diluted NaOH solution into the pipeline automatically. So it is with precise metering, an overall light design, and accurate speed control, free from the heat source and electromagnetic interference. The operator can appropriately adjust it according to changes in water volume and flow rate by the metering pump, and the agents can be added automatically. Furthermore, the metering pump is linked with the second high-pressure pump to strictly control the pH value of the second reverse osmosis feed water and ensure the stable water quality of the secondary RO water production.

E. Intermediate water tank

Store the first-stage RO production water and provide a stable and sufficient water source for the subsequent equipment water. The water tank is equipped with a liquid level controller, which controls the start and stops of the first-stage RO and secondary high-pressure pump through the level of the water tank: when the water tank level is insufficient, the first-stage RO automatically replenishes the water tank, and when the water tank is full, the first-stage RO automatically stops filling the water tank; when the water tank is short of water, the secondary high-pressure pump automatically stops to prevent idling, and when the water tank level recovered, the secondary high-pressure pump automatically starts to supply water for the subsequent equipment.

3. EDI electric desalination system

It is used for deep purification and desalination of RO production water to meet the demand for ultra-pure water.

A. EDI booster pump

It is used to boost the pressure and flow rate of the EDI water supply and is linked with EDI equipment.

B. EDI device

RO production water is evenly distributed to the freshwater chamber after entering the EDI module. Trace ions not removed from the water are adsorbed by ion exchange resin in the freshwater room. Under the action of the DC electric field, the ions in the freshwater chamber are transferred to the concentrated water chamber towards the opposite electrode, thus producing ultra-pure water. In addition, under an electric field, the water molecules in the freshwater room are dissociated into hydrogen ions and hydroxide ions on the surface of the ion exchange resin, thus continuously regenerating the resin.

4. Post-treatment system

It mainly includes UV sterilization treatment and a pure water tank.

A. UV sterilization device

In ultrapure water preparation, the degradation of TOC (total organic carbon) is crucial. UV-180nm single wavelength UV technology is used through high-dose UV-180 UV light catalysis, .OH, and hydroxyl radicals are generated in the water to oxidize and degrade the organic matter in the water to reduce the TOC content. The practical service life of the lamp is 6000 hours, and the standard chamber material is 304 stainless steel with a polished mirror design inside and outside.

B. Purified water tank

It is used to store the EDI production water and provide a stable and sufficient water source for the subsequent equipment. The water tank comes with a level controller, which controls the start and stops of the first and second high-pressure pumps through the level of the water tank: when the status of the water tank is insufficient, the water tank is automatically refilled, when the water tank is full, EDI automatically stops filling the water tank.

RO system characteristics

1. Automatic flushing device

When the reverse osmosis plant is in operation, the feed water enters the reverse osmosis system and divides in two ways. One way passes through the surface of the reverse osmosis membrane to become production water, and the other way along the surface of the reverse osmosis membrane moves in parallel and gradually concentrates. These concentrated water streams contain many salts, organic matter, colloids, microorganisms and bacteria, viruses, etc. During the regular operation of the reverse osmosis system, the feed water/concentrated water flows along the surface of the reverse osmosis membrane at a specific flow rate. Therefore, it is challenging to deposit these pollutants. Still, if the reverse osmosis system stops operating, these pollutants will be immediately deposited on the surface of the membrane and cause contamination to the membrane elements. Therefore, it is necessary to set up an automatic flushing system in the reverse osmosis system to prevent the deposition of these pollutants by using clean production water to flush the surface of the membrane element when it is out of operation.

2. Automatic control system

This system operates fully automatically, including flushing sand/carbon filter, automatic cleaning of reverse osmosis unit, automated protection system for pressure and liquid level, etc. Moreover, the electrical apparatus adopts PLC programmable controller, which genuinely achieves unattended and uninterrupted operation.

RO plant is one of the world’s most advanced water treatment facilities for making pure and ultra-pure water. With low operation cost, easy operation, and reliable operation, it is the first choice of users for producing purified water and ultra-pure water equipment.

To learn more about domestic sewage solutions, please click the button below to contact us. Our senior technical engineers will provide you with free services at the first time.