Hollow Fiber Membrane

All Products

Want More Information ?

More Wastewater Solution ?

1. No Filament Breakage and No Peeling

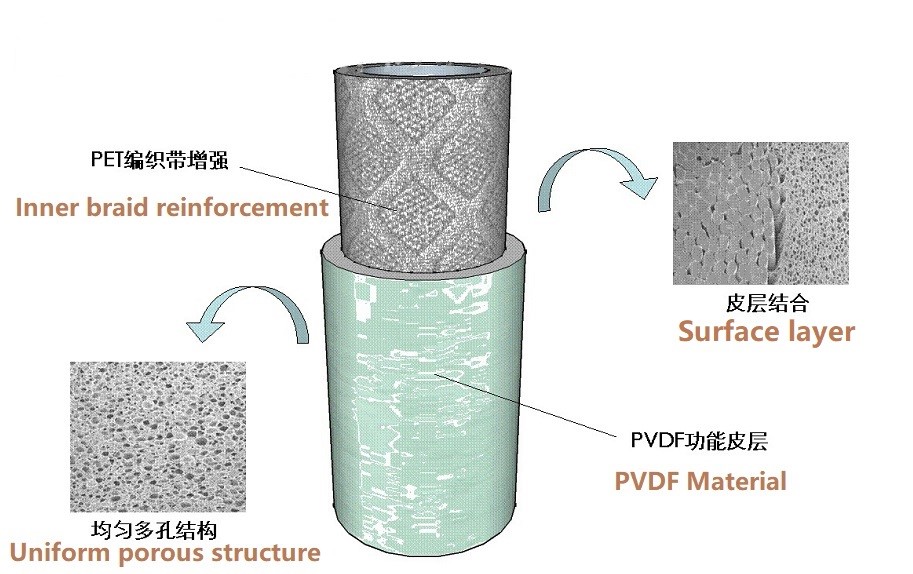

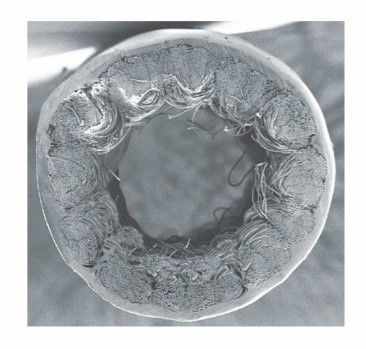

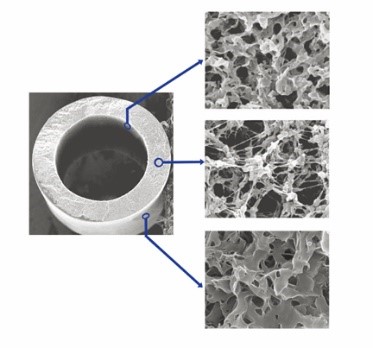

EcoLan’s hollow fiber membrane filament adopts PET woven mesh tube as the liner and is firmly compounded with PVDF functional layer. As a result, the tensile strength of a single filament ≥ 100.0MPa and peeling strength ≥ 1.0MPa is 3~8 times the membrane filament produced by the NIPS method and three times the membrane filament produced by the standard TIPS method. EcoLan completely solves the problems of extension deformation, filament breakage, and easy damage and peeling of the functional layer of hollow fiber membrane filament and ensures the long-term stability of production water.

2. High Flux and Long Service Life

3. Anti-oxidation and Acid & Alkali Resistance

4. Dry Transportation and Storage

The permanently hydrophilic modified PVDF material and large porosity (≥60%) membrane structure endow the membrane filaments with strong water permeability and higher operating flux and enable dry transport and storage of the membrane.