Industrial Wastewater Solution

Industrial Wastewater Solution

Table of Contents

Industrial wastewater refers to the wastewater produced in the process of industrial production, and the pollutants in the wastewater are diverse, complex, extraordinary, and difficult to treat. Moreover, with the development of the economy, the pollution of water resources by wastewater is also becoming more and more serious, and the scope involved is gradually expanding, which has caused a corresponding impact on human health and safety. So how to treat industrial wastewater?

Industrial wastewater treatment methods are different in different industries and from various sources, and we should select suitable treatment methods according to specific situations. Usually, physical and chemical processes are first used for pretreatment to improve their biochemical properties. Then MBR membrane method treatment is continued before the wastewater can meet the discharge requirements.

Treatment methods of industrial wastewater

As per the degree of removal of pollutants in industrial wastewater, we divide it into primary, secondary, and tertiary treatments. In practice, we combine the three-stage treatment method to make the water quality of wastewater reach reuse or higher discharge standard.

1. Primary treatment

It is mainly pretreatment, a commonly used physical or straightforward chemical method to remove solids, colloidal substances, oil slicks, or heavy oil in industrial wastewater. It can use water quality and quantity adjustment, natural sedimentation, and floating and oil separation. However, the BOD removal rate of the wastewater after primary treatment is only about 20%, which still needs to be more suitable for direct discharge.

2. Secondary treatment

Mainly refers to the aerobic and anaerobic biological treatment, which can substantially remove the colloidal and dissolved organic matter in the industrial wastewater and can generally remove about 90% of the biodegradable organic matter, 90% to 95% of the suspended solids, and 80% to 90% of the BOD. Secondary treatment can significantly improve the water quality and even make the effluent reach the discharge standard. However, there is still a considerable amount of COD in the wastewater, and sometimes there is a high level of color, smell, and taste.

3. Tertiary treatment

Also called advanced treatment, the purpose is to remove organic pollutants further and dissolve inorganic impurities that are difficult to biodegrade in industrial wastewater. In addition, it releases various viruses, bacteria, phosphorus, nitrogen, and other substances and finally reaches the water quality standard of groundwater, industrial water, or close to domestic water. Commonly used are MBR membrane separation technology + chemical treatment method.

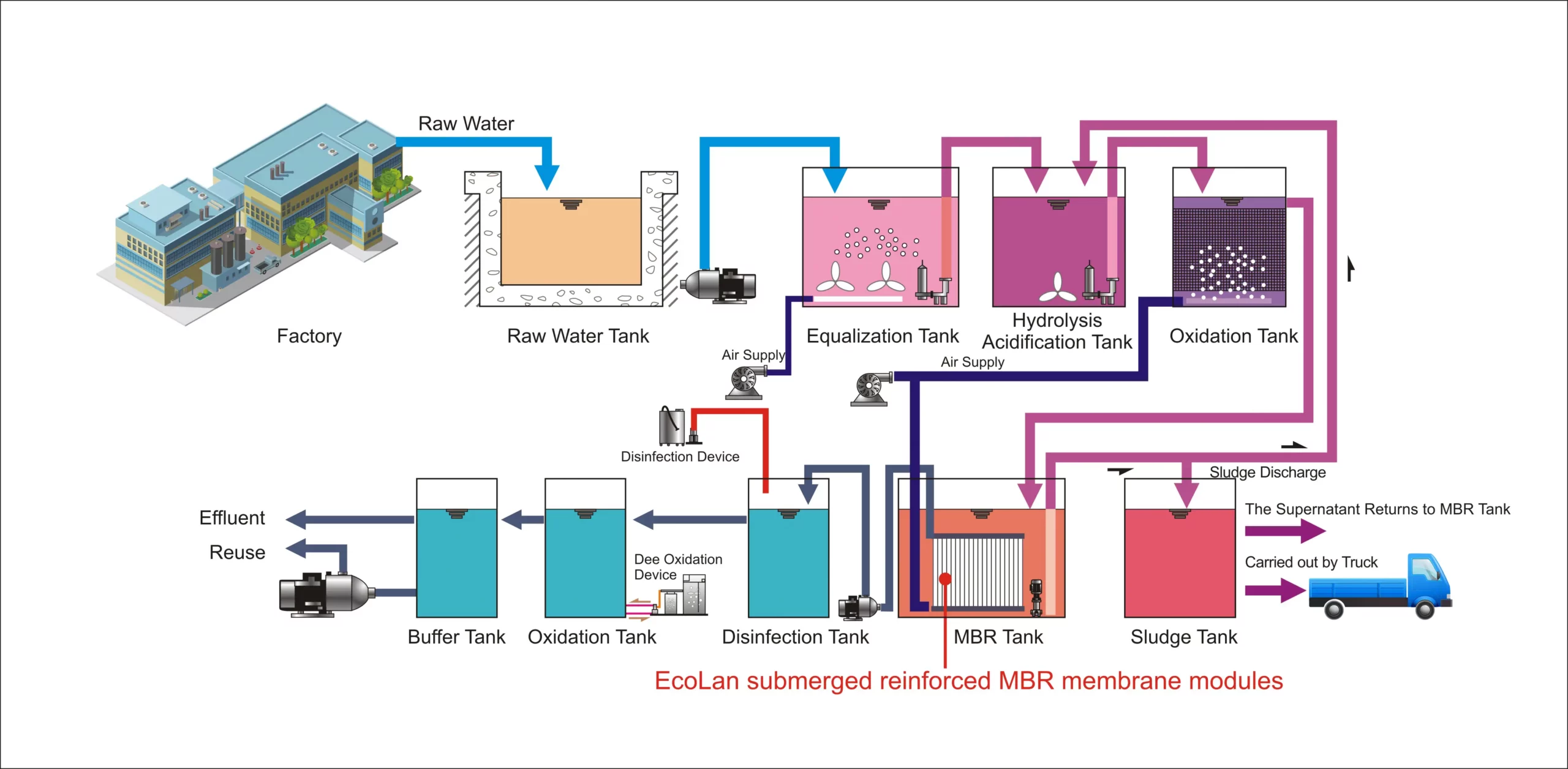

The industrial wastewater treatment process

MBR membrane wastewater treatment technology can significantly improve the treatment efficiency and maintain a high concentration of biofacies and excellent effluent effect. In addition, it can remove pollutants such as organic matter and ammonia nitrogen in the water and has obvious advantages that many other biological treatment technologies cannot match. For example, adopt a typical A2O+MBR process to treat industrial wastewater, detailed in the following diagram.

Process flow description

1. Wastewater pretreatment

The pretreatment stage mainly uses a coarse grid, fine grid, primary sedimentation tank, and regulating tank. The coarse and fine grids filter out large floating materials. The core of the regulating tank is to adjust the sewage flow and water quality to ensure the regular operation of subsequent equipment and energy saving. Acidic and alkaline wastewater are also mixed and neutralized in the regulating tank to achieve the purpose of pH adjustment. In addition, the short-term discharge of high-temperature industrial wastewater can also play a role in regulating.

2. Anaerobic tank

By controlling the biochemical system with dissolved oxygen ≤ 0.2mg/L, the large-molecule organic matter is decomposed into small-molecule organic matter, which facilitates the subsequent process and removes part of the COD, while it can also play a role in releasing phosphorus.

3. Anoxic tank

It mainly degrades organic matter and removes ammonia nitrogen from wastewater by denitrification under 0.2<DO<0.5mg/L. Under the action of denitrifying bacteria, the nitrate nitrogen produced in the nitrification process is reduced to nitrogen and dissipated into the air. The organic matter that is difficult to degrade is also decomposed to improve the BOD/COD ratio, increasing the feed water’s biochemical properties and creating favorable conditions for the aerobic biochemical process. In addition, due to the adsorption of sludge reflux, it can partially remove phosphorus and improve the treatment effect.

4. Aerobic tank

Maintain the dissolved oxygen content in the sewage at about 4mg/L through aeration and oxygenation, which is suitable for the growth and reproduction of aerobic microorganisms, to further decompose the decomposed organic matter into carbon dioxide and water, and completely decompose the organic matter. At the same time, the phosphorus in the wastewater is removed by the excessive absorption of phosphorus by PAOs.

5. MBR Membrane pool

MBR membrane bioreactor is a place for microorganisms to degrade organic matter, and it can retain microorganisms with a long generation cycle to realize deep purification of industrial wastewater. At the same time, the nitrifying bacteria can fully reproduce in the membrane system, and the nitrification effect is noticeable, providing the possibility of removing nitrogen and phosphorus. A sludge return pump is installed in the MBR membrane tank, which can return the muddy water to the anoxic tank for denitrification to ensure the wastewater’s total nitrogen can reach the water reuse standard. The sludge return pump comes with a sludge discharge port, which can discharge sludge regularly (1~3 months) to ensure the concentration of activated sludge (8000~15000mg/L) in the membrane bioreactor to meet the demand of its stable operation for a long time.

6. Disinfection device

Commonly used disinfection methods include chlorine disinfection, UV disinfection, and ozone disinfection, which can be selected according to the nature of the wastewater. At present, UV disinfection is relatively common, with the characteristics of fast disinfection and high efficiency, and can be sterilized by UV irradiation for a few tens of seconds, with an average removal rate of 98% for E. coli and 96.6% for total bacteria. At the same time, UV disinfection does not affect the water’s physical properties, the chemical composition does not increase the odor of the water, and simple operation is easy to manage and achieve automation.

7. Cleaning tank

As a production water storage tank of the MBR system, it is also the MBR membrane cleaning and dispensing pool and a head tank to prevent siphonage when the suction pump stops running.

Characteristics of MBR membrane technology

- Degrade organic matter in the wastewater, and nitrifying bacteria nitrify NH3-N to NO3-, which removes more than 95% of organic matter and more than 97% of ammonia nitrogen.

- The pretreatment process is simple and does not require a large amount of chemical dosing, and the corresponding operation process is simple.

- Up to 99% water recovery allows the operator to reduce the pressure on the MBR by lowering the recovery rate as the feed water deteriorates while producing the same amount and quality of purified water.

- The system uses process monitoring systems, including flow transmitters and pressure transmitters, etc. Therefore, we can use this highly controlled system approach to design the most flexible membrane systems.

- Air scrubbing ensures reliable operation of the MBR membrane system under all inflow conditions

- Automatic backwashing ensures improved overall membrane flux at lower transmembrane pressure differentials.

- Small footprint, only 30~50% of the traditional technology, and long service life, up to 70,000 hours of continuous operation, with MBR membrane breakage rate of less than 1%

Application of MBR membrane technology

Through the practical application of membrane bioreactor technology in industrial wastewater treatment and reuse, it is evident that after effectively solving the technical problems of high concentration biological activity stability, membrane flux maintenance, and amplification effect, the industrial wastewater treatment by membrane bioreactor technology can effectively degrade organic pollutants and other nutrients in the water. Moreover, it has excellent impact load resistance, high biological treatment efficiency, and a small footprint.

The effluent of the MBR membrane system can be directly reused in the cooling circulating water system or used as pretreatment feed water for advanced treatment such as nanofiltration or reverse osmosis. Therefore, enterprises need to reduce the discharge of pollutants and improve the wastewater reuse rate, which is worthy of vigorous research and promotion. To some extent, membrane bioreactor technology comes from wastewater’s traditional biological treatment process. Still, it has reached a height that conventional natural treatment technology is challenging to achieve.

Therefore, membrane bioreactor technology can be competent or better than traditional biological treatment technology as long as the wastewater can be treated by conventional natural treatment technology. But, of course, membrane bioreactor technology is not a panacea. Therefore, we must combine it with traditional wastewater pretreatment and other treatment methods to maximize its effectiveness to achieve the large-scale engineering application of membrane bioreactor technology.

Prospect of MBR membrane technology

Membrane wastewater treatment technology is essential in industrial wastewater treatment and recycling. In demand for high-standard treatment and discharge of wastewater and the orientation of low-carbon green development, it is necessary to evaluate the potential comprehensively and continuously promote the energy saving and consumption reduction of membrane wastewater treatment technology, accelerate the coupling and application of innovative membrane wastewater treatment technology and resource-based energy technology.

At the same time, it is necessary to coordinate the recycling of production water from the MBR system and innovate and develop the recycling and sustainable utilization technology of membrane materials. Therefore, continue to promote the digitization and intelligent operation and maintenance of membrane wastewater treatment systems and promote the continuous innovation and iterative upgrading of membrane wastewater treatment technology in the direction of green and low-carbon development.

To learn more about Industrial Wastewater Solution, please click the button below to contact us. Our senior technical engineers will provide you with free services at the first time.