Technical Solution

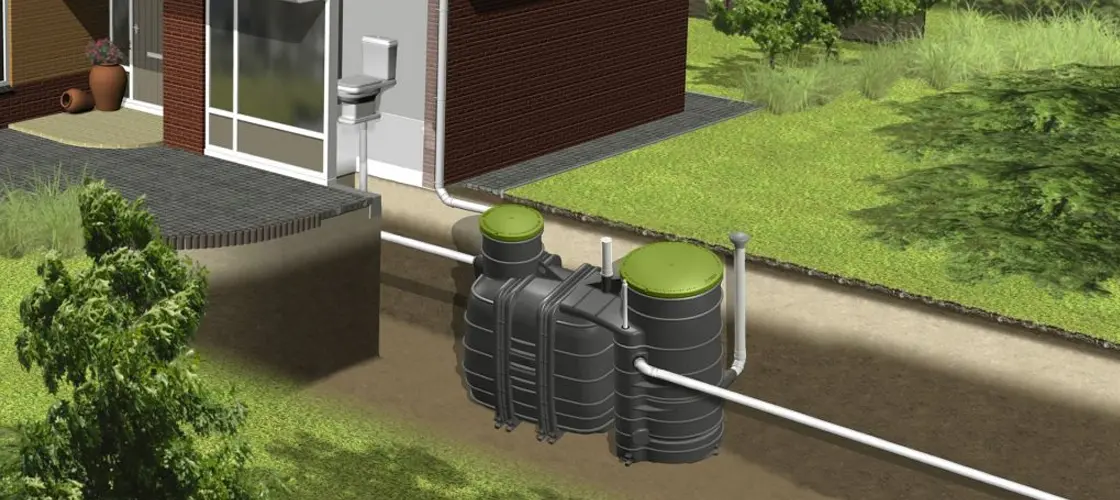

Domestic Sewage

Domestic sewage is mainly the wastewater residents produce in their daily lives, including washing water, bathing water, kitchen water, toilet water, etc. Therefore, its daily discharge is significant and needs to treat to meet the standards before release. Furthermore, untreated domestic sewage contains many organic and inorganic pollutants, which will pollute the water environment and lead to the eutrophication of water bodies. It will also affect the self-purification of water bodies and destroy the ecological water balance when discharged directly into water bodies. Therefore, collecting domestic sewage effectively and choosing an appropriate treatment process is very important.

Industrial Wastewater

Industrial wastewater refers to the wastewater produced in the process of industrial production, and the pollutants in the wastewater are diverse, complex, extraordinary, and difficult to treat. Moreover, with the development of the economy, the pollution of water resources by wastewater is also becoming more and more serious, and the scope involved is gradually expanding, which has caused a corresponding impact on human health and safety. So how to treat industrial wastewater?

Industrial wastewater treatment methods are different in different industries and from various sources, and we should select suitable treatment methods according to specific situations. Usually, physical and chemical processes are first used for pretreatment to improve their biochemical properties. Then MBR membrane method treatment is continued before the wastewater can meet the discharge requirements.

Pure & Ultrapure Water

The traditional preparation process of pure and ultrapure water is usually made by ion exchange resin. Still, the ion exchange resin requires frequent regeneration, which is both costly and labor-intensive. EcoLanTM adopts reverse osmosis technology, or the process combined with EDI to prepare pure water and ultra-pure water, after years of practice and experience, which has the advantages of low operating cost and high operational reliability compared with the traditional process. The reverse osmosis technology is advanced, stable, and reliable, while the EDI technology does not require chemical regeneration, no wastewater discharge, and low operating cost.