Domestic Sewage solution

Domestic Sewage Solution

Table of Contents

A brief analysis of the source and treatment of domestic sewage

Domestic sewage is mainly the wastewater residents produce in their daily lives, including washing water, bathing water, kitchen water, toilet water, etc. Therefore, its daily discharge is significant and needs to treat to meet the standards before release. Furthermore, untreated domestic sewage contains many organic and inorganic pollutants, which will pollute the water environment and lead to the eutrophication of water bodies. It will also affect the self-purification of water bodies and destroy the ecological water balance when discharged directly into water bodies. Therefore, collecting domestic sewage effectively and choosing an appropriate treatment process is very important.

For a long time, the secondary biological treatment of domestic sewage mainly adopted the activated sludge process, which is currently the most widely used secondary natural treatment process in the world, with the advantages of high treatment capacity and good effluent quality. However, there are widespread problems such as increased infrastructure costs, high operating costs, high energy consumption, complex management, sludge bulking, sludge floating, and other issues. It also cannot remove inorganic nutrients such as nitrogen and phosphorus.

Due to the efficient separation of the membrane for MBR technology, the effect is much better than traditional sedimentation tank. As a result, the treated effluent is clear, suspended matter and turbidity are close to zero, bacteria and viruses are substantially removed, and the effluent quality is higher than the general wastewater discharge standard. It can be directly reused as non-potable municipal miscellaneous water, such as ground cleaning, greening, firefighting, etc. At the same time, MBR membrane separation technology also makes microorganisms wholly trapped in the bioreactor so that the system can maintain a high concentration of microorganisms. It not only improves the overall removal rate of pollutants in the reactor and ensures good effluent quality but also has good adaptability to various changes in influent load (water quality and water quantity). And resistant to shock load so that it can obtain high-quality effluent quality.

Process flow and description

The dissolved CODcr and BOD5 of domestic sewage are both high, and the biochemical properties are generally good. Therefore, considering the requirements for the treatment of domestic wastewater, as well as the environmental impact and land saving, we decided to adopt the process scheme with the biofilm method as the core treatment unit, combining our previous successful experience in domestic sewage treatment.

MBR biofilm reactor combined membrane separation technology and activated sludge biotechnology, which differs from the activated sludge process. It does not use a sedimentation tank for solid-liquid separation. Still, it uses a hollow fiber membrane instead of a sedimentation tank, so it has high-efficiency solid-liquid separation performance. At the same time, using the membrane’s characteristics, the activated sludge is not lost with the effluent, and the activated sludge with a high concentration of 8000~12000mg/L is formed in the biochemical tank so that the pollutants are decomposed thoroughly. As a result, the effluent water quality is guaranteed to be good and stable.

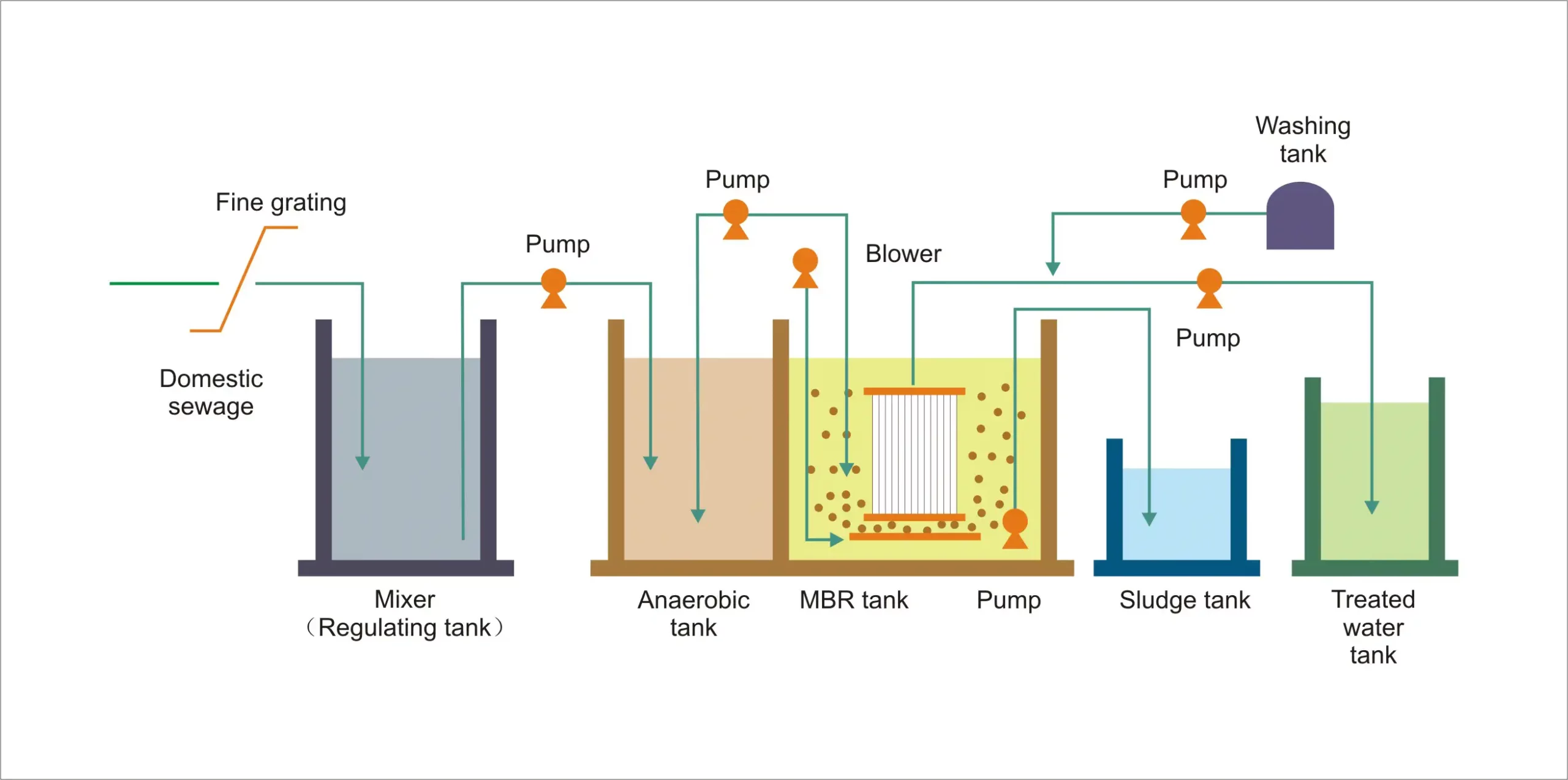

The following is the process flow diagram. We use the most mature anaerobic (facultative) oxygen + contact oxidation + MBR membrane filtration + disinfection treatment process on domestic sewage, including three stages of raw water pretreatment, biological treatment, and subsequent treatment. The process is simple and easy to manage and operate. First, wastewater is merged into the sewage treatment system through the pipeline. Next, the grid removes the large granular and fibrous impurities. Then it flows through the hydrolysis acidification tank, contact oxidation tank, and MBR membrane tank one by one, according to the specific structure in the system. Finally, the effluent reaches the discharge or reuse standard after disinfection.

1. Pretreatment section

Pretreatment section treatment structures include grille wells and regulating tanks. Domestic sewage flows into the grille well from the septic tank. It enters the regulating tank after removing most animal and vegetable oils and many suspended solid impurities from the sewage through the plane grille. Then the water quality and quantity are homogenized in the regulating tank, which can reduce the scale of the sewage treatment project, lower the investment and ensure the subsequent treatment effect.

2. Biological treatment section

The sewage from the regulating tank is lifted to the MBR membrane bioreactor by the submersible pump, “hydrolysis acidification + contact oxidation + MBR membrane filtration” is the core of this project, which mainly removes BOD, COD and nitrogen, and phosphorus in the sewage.

3. Follow-up treatment section

It mainly includes UV disinfection and a clean water tank.

Selection of each unit process

1. Septic tank

The underground, reinforced concrete structure used to collect domestic sewage is a treatment facility that uses the principle of sedimentation and anaerobic fermentation to remove suspended organic matter from domestic sewage and belongs to the primary transitional domestic treatment.

2. Grille well

Grille mainly has two roles; one is to intercept large floating objects to prevent blocking the submerged pump, and the second is to intercept smaller floating objects to avoid affecting the treatment efficiency of subsequent treatment units. The basic principle is wire mesh filtration, and the workforce must remove the accumulated impurities on time. The grille is generally made of stainless-steel mesh with a gap of 5~10mm, and the size is determined by the septic tank’s width and the elevation of the incoming water pipe.

3. Regulating tank

It is also an underground, reinforced concrete structure with a cast-in-place cover because the sewage source determines the incoming water’s unevenness. So, set up the regulating tank to homogenize the water quality and quantity of sewage, adjust the pH, and reduce the impact of shock load on the subsequent treatment unit, to create good conditions for the next treatment. Two submersible pumps are set up at the outlet of the regulating tank, one for use and one for backup, to lift the effluent of the regulating tank to the MBR membrane bioreactor. The sludge in the regulating tank should be emptied regularly and discharged after harmless treatment.

4. MBR membrane bioreactor

MBR bioreactor mainly consists of an anoxic zone, aerobic zone, membrane separation zone, clear water tank, operation room, reflux pump, and UV disinfection device. The sewage in the regulating tank is lifted into the anoxic zone of the bioreactor by the submersible pump; after anoxic treatment, it flows into the aerobic area, and the aeration system is opened through the PLC control cabinet to oxygenate. The sewage enters the MBR membrane tank at a specific flow rate to contact the MBR membrane. The membrane separation function and the suspended activated sludge work together to purify the sewage. The MBR membrane tank is mainly composed of a membrane module, self-priming pump, and aeration device, and the filtered water from the membrane module enters the clear water tank after UV disinfection. At the same time, the concentrated solution returns to the anoxic zone. The backwash pump uses the water in the clear water tank to backwash the membrane module to delay membrane fouling, and the flushed effluent is returned to the regulating tank. If chemical cleaning of the membrane is required, the inlet valve and the sewage circulation valve are closed, and the membrane is cleaned according to the chemical cleaning procedure.

5. Operation room

The leading equipment in the operation room of a typical MBR membrane system includes two self-priming pumps (working in rotation), one backwash pump, two blowers (working in rotation), one sludge reflux pump, one outlet electric valve, one backwash electric valve, and a low liquid level protection switch for the MBR membrane module, a low liquid level protection switch for the backwash pump and a high liquid level alarm switch for the membrane pool. It can also add other configurations according to actual requirements.

6. Automatic control

The sewage treatment system has automatic and manual control functions; the system usually operates automatically, that is, it automatically starts and stops the device according to the liquid level of the domestic sewage regulating tank. All equipment can automatically run and will also alarm when a failure occurs. MBR membrane system’s automatic operation steps are as follows.

| Steps | 1 | 2 | 3 | Remark | |

| Working | Stop | Backwashing | |||

| Normal operation | Outlet electric valve | O | |||

| Backwashing electric valve | O | ||||

| Suction pump | O | 2-hour work shifts | |||

| Backwashing pump | O | ||||

| Blower | O | O | O | Two sets, every 240~360 minutes of work rotating work | |

| Running time | 480s | 120s | Backwashing every 120~240 minutes, 3~5 minutes each time | ||

| Protection design | MBR membrane tank high-level switch | The sewage level in the MBR membrane tank is about to overflow the membrane tank, which is the high liquid level. When the water level reaches a high fluid level, an alarm is issued, the sewage lifting pump stops running, and the membrane tank no longer feeds water. | |||

| MBR membrane tank low-level switch | The liquid level is low when the sewage in the MBR membrane tank is about to be lower than the fluid level at the top of the MBR membrane module. When the liquid level reaches a low level, the suction pump must stop running. | Mainly prevent the suction pump from pumping air to avoid damage to the pump and membrane modules | |||

| Sludge return pump | The return pump is used to control the sludge concentration. Generally, the sludge concentration is controlled at 6000-80000mg/L and should be avoided exceeding 12000mg/L. | Run for 240 minutes and stop for 60 minutes, to be set according to sludge concentration. | |||

| Manual operation | Dosing pump | Manual turn-on operation | Online dosing for maintenance cleaning | ||

Note:

1 “O” means the valve is open or the pump is running.

2 The program cycle is “1→2→1→2” in regular operation.

Linkages and synergies between unit processes

Each unit has different removal objects in domestic sewage treatment, but they also coordinate with each other. Firstly, domestic sewage flows from the septic tank into the grille well and enters the regulating tank after removing a large amount of suspended solid impurities through the flat grille. The water quality and quantity are regulated in the regulating tank, which effectively prevents the impact of water shock load on the subsequent treatment units. The domestic sewage is lifted by the submersible pump into the MBR membrane bioreactor and first enters the hydrolysis acidification treatment unit. After hydrolysis acidification treatment, the suspended solids and various organic pollutants are partially removed, and the biodegradability is improved, which improves the treatment efficiency of the subsequent treatment unit. Then the sewage flows into the contact oxidation treatment unit, and the organic pollutants are effectively removed under the action of aerobic microorganisms. Next, the sewage of the aerobic tank enters the MBR membrane tank to remove the suspended solids and further degrades the organic matter in the water. Finally, the effluent from the membrane tank is pumped by the self-priming pump and enters the clear water tank after UV disinfection. The water in the clear water tank can be discharged or reused up to the standard.

Influence of equipment selection on operation and maintenance

1. Pump selection

A sewage lifting pump is recommended to use a submersible pump; easy to install and operate, simplifies the civil structure, reduces the project cost, and easy operation and manage, and is safe and reliable.

2. Blower selection

Suggest choosing a high-efficiency, energy-saving, low-noise rotary blower.

3. Membrane self-priming pump

Recommend MBR membrane self-priming pump to use a light stainless steel self-priming pump.

4. MBR membrane

Strongly recommend choosing EcoLanTM high-quality hollow fiber membrane.

Energy saving

In this program, We fully considered energy saving in the selection of domestic sewage treatment process and single process design, such as: using higher power efficiency, bottom aerator for blast aeration, using energy efficient rotary blower; process flow is simple and smooth, minimizing turns and detours, reducing sewage and sludge lifting head and saving power consumption. At the same time, the design of this scheme uses self-flow as much as possible to minimize head loss to save resources.

From the above, we can see that the superiority of the MBR process for treating domestic sewage is incomparable to other treatment processes. Although the operating cost of MBR is slightly higher than conventional biological treatment methods, the effluent of MBR technology can achieve the purpose of water reuse. With the progress of membrane manufacturing technology, the improvement of membrane quality, and the reduction of membrane manufacturing cost, the investment of MBR will also be significantly reduced and has a broad application prospect.

To learn more about domestic sewage solutions, please click the button below to contact us. Our senior technical engineers will provide you with free services at the first time.