Who Determines the Membrane Flux of MBR System

Table of Contents

As a new type of wastewater treatment technology, the essence of membrane bioreactor is the effective combination of activated sludge and high-efficiency membrane separation. The MBR process relies on the filtration function of the membrane to retain the activated sludge in the bioreactor, using aerobic bacteria and other microorganisms to achieve the decomposition and absorption of pollutants and then achieve the purpose of cleaning wastewater.

In the purification work, users must reasonably handle the MBR system’s membrane flux due to various limiting factors. Either too high or too low a flux will lead to a severe impact on the purification function of the membrane itself. On the one hand, it will affect the service life of the membrane itself, and on the other hand, it is not conducive to the orderly development of wastewater treatment work.

What is MBR membrane flux?

Membrane flux (or permeation rate) is a vital process operating parameter of the membrane separation process, usually referring to the amount of fluid passing through a unit membrane area per unit of time, generally expressed as m3/(m2*s) or L/(m2*h) (or as m/s). The fluid here is the production of water for the MBR process.

There are various ways to call membrane flux, and those new to membrane treatment may need clarification. However, several typical membrane fluxes are as follows, depending on the actual time.

Average Membrane Flux

It refers to the amount of product water through a unit membrane area within the design time and usually refers to the daily average flux (the total amount of product water in 24 hours averaged to the unit hour and the amount of product water in the unit area); there are also references to monthly average flux and annual average flux.

Operating Membrane Flux

It refers to the amount of product water per unit time and unit area during the actual operation of the membrane. For example, operational flux includes the sum of product water and backwash water, etc.

Peak Membrane Flux

The amount of product water per unit time and unit area under peak water conditions.

Design membrane flux

It refers to the membrane system flux that is considered according to the service life and usage environment; usually, the design unit refers to the design flux, which is equivalent to the membrane system operating flux.

Understanding the actual meaning of each flux helps the system design to be reasonable and accurate. For system design, we need to determine the operating and average flux of the membrane system. Once the system operating mode and other parameters are designed, a defined conversion relationship exists between the operating and design flux. Therefore, for the existing membrane system, we only need to determine one of the fluxes and design according to it.

Why is MBR membrane flux important?

As mentioned above, MBR membrane flux refers to the amount of product water, and the higher the flux, the more water the MBR membrane will produce in a given amount of time. For example, a low-flux MBR membrane produces 0.5 tons of water per hour, while a high-flux membrane produces 1 ton of water per hour, which looks clear. Therefore, flux is critical and is an essential indicator of how good an MBR membrane is.

Membrane flux is determined by both the external driving force and the resistance of the membrane, in which the nature of the membrane itself plays a decisive role. The reduction of membrane flux is mainly due to the blockage of the membrane channels, resulting in a decrease in water output. If there is a severe drop in water production, it is time to replace the membrane element. At the same time, the membrane flux also determines the selection of the supporting membrane elements. Finally, the actual operating flux is compared with the standard membrane flux to determine whether the membrane is working correctly.

What factors influence MBR membrane flux?

Membrane flux can be affected by various factors, the most common of which are as follows.

Temperature

The higher the temperature, the higher the membrane flux because the higher temperature will reduce the activated sludge mixture’s viscosity and permeation resistance. In the case of membrane bioreactors, the optimal operating temperature is generally controlled between 15°C and 35°C. Therefore, when encountering a low-temperature environment, it is necessary to consider the decay of membrane flux under low-temperature operation.

Aeration (membrane surface flow rate)

A reasonable amount of aeration can sufficiently increase the surface flow rate of membrane elements, and the increase of surface flow rate can improve the mass transfer coefficient of concentration polarization, thus reducing the concentration polarization effect and improving the operating flux of the membrane. However, increasing the aeration amount and increasing the membrane surface flow rate indefinitely is not good. Too much aeration brings too much energy consumption. Furthermore, after a specific limit is exceeded, the effect of increasing aeration or membrane surface flow rate on improving the mass transfer coefficient will rapidly diminish. Therefore, proper aeration (membrane surface flow rate) design is crucial to the impact of membrane operating flux.

Activated sludge mixture in the membrane tank

The viscosity, MLVSS/MLSS, and sludge concentration of the activated sludge mixture affect the flux of the membrane element, and controlling the appropriate sludge concentration is beneficial to the flux stability. Usually, users must control the membrane tank’s sludge concentration between 5000~10000mg/L, and the viscosity is at most 50MPas.

Membrane tank water quality

The oil content, hardness, alkalinity, heavy metals, and other indicators of the raw water quality in the membrane system will also cause the pollution of the membrane element, which will affect the membrane flux. Therefore, when heavy metals, hardness, and other indicators exceed the standard, it is necessary to carry out reasonable pretreatment of the raw water to meet the feed water requirements before entering the membrane filtration.

Other factors, such as feed water pH, membrane operating pressure, solids, and other factors, will also affect the operation of the membrane system, affecting the stability of the membrane flux and requiring careful consideration of all aspects.

What are the methods of designing MBR membrane flux?

The selection of design flux needs to consider the system stability and the rationality of the cleaning cycle and the project investment budget, subsequent membrane replacement cost, and other factors. Therefore, we must evaluate various aspects for the optimal operating flux that balances all conditions.

The optimal operating flux requires using as few membrane elements as possible while maintaining a reasonable life span and maintenance cycle to reduce the investment and replacement cost of the membrane elements. Generally, there are several methods for reference.

1. According to the EcoLan guidebook

For typical water quality, membrane flux can be consulted in our membrane technology manual. We will rigorously test the operation of the membrane elements in each routine use environment and give a guideline. Usually, this guideline is a reasonable flux for stable operation. However, because water quality varies from time to time and region to region, even for the same water quality type, a particular factor should be taken when using the membrane manufacturer’s guideline design flux to ensure the system’s stability.

2. According to the project water quality type

With the dramatic increase in membrane applications, there is some consensus in the industry on the design flux selection for membrane systems in various water bodies. Therefore, in addition to referring to the manufacturer-specific design fluxes, the design process can also be based on the industry’s consensus on the design fluxes for various water types. Design units and engineering firms generally choose the following fluxes for hollow fiber membrane products for membrane bioreactors for standard water quality.

| Number | Water Quality Type | Recommended Design Flux(L/m 2h) | Remark |

| 1 | Municipal sewage | 15~25 | |

| 2 | General industrial wastewater | 12~20 | |

| 3 | Oily wastewater | 10~15 | Animal and vegetable oil ≤ 30mg/L, Mineral oil ≤3mg/L |

| 4 | Difficult to treat industrial wastewater such as printing and dyeing wastewater | 12~18 | |

| 5 | Garbage leachate | 4~8 | Membrane tank pH≤8 |

3. According to the data of small and medium test

For some unconventional water quality, in the absence of relevant parameters to guide the situation, it is necessary to carry out a small and medium-sized test of the system to determine the membrane bioreactor using membrane products for this type of water quality adaptability, the selection of flux, cleaning cycle, and other issues.

4. According to the critical flux

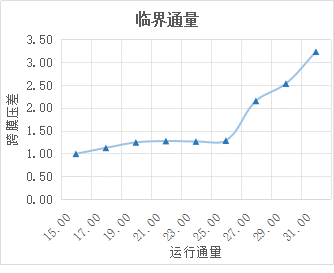

The critical flux is the maximum flux in which the transmembrane pressure difference does not rise significantly with operating time under certain operating conditions (temperature, sludge concentration, aeration strength, etc.).

The critical flux is related to the operating environment, i.e., operational stability, sludge concentration, and aeration strength, as mentioned above, as well as to membrane materials, membrane structure, and other factors. Therefore, the significance is to examine and determine the operating flux limit of the membrane product in a specific operating environment. The determination methods are usually the constant flux stepwise increment method, constant pressure stepwise increment method, and working curve method.

Determining the critical flux provides an understanding of the operating limits of the system under specific water quality and process conditions. However, the critical flux can change as the membrane operating environment changes, and sudden increases in membrane operating pressure can be summarized in many cases as membrane supercritical operation due to changes in operating conditions. Therefore, a stable working environment with a reasonable cleaning cycle is crucial for the selected number of membranes.

What is the reason for the MBR membrane flux decline in membrane filtration?

After operating for some time, MBR membrane systems may find that the membrane flux decreases faster and does not reach the design capacity. We have summarized the common causes for your reference.

- Serious sludge accumulation in the sludge tank after long-term wastewater treatment system operation, bio-viscosity formation, and poor settling function.

- Inadequate raw water pretreatment, with pollutants, seriously exceeding the treatment capacity of the wastewater treatment system.

- Permanent damage to the MBR membrane can no longer produce sufficient water quantity and quality.

- The MBR membrane is temporarily damaged after contamination, such as pore blocking, and needs to be cleaned to restore water production capacity.

- It also relates to the membrane system working environment, selection design, installation & construction, and operation management.

In addition, the performance of the membrane product itself is also an essential point. For the MBR system, the anti-pollution and hydrophilic properties of the membrane itself have a significant impact on the flux, so it is necessary to use a reinforced MBR membrane sheet with permanent hydrophilic properties, strong anti-pollution properties, no peeling, and no filament breakage, to ensure the water quantity and quality of product water.

What are the solutions for MBR membrane flux decline in the membrane system?

The reasons for the decline of MBR membrane flux have been detailed in the previous section, and we suggest that solutions can be given by considering the following aspects.

Shorten the sludge age. The membrane tank should be discharged in time to keep its settling performance reasonable and reduce the pollution among microorganisms.

- Strengthen the raw water pretreatment and timely monitor the membrane tank water quality to meet the MBR system feed water requirements.

- Use high-performance MBR membranes and promptly replace permanently damaged MBR membrane elements.

- Regularly clean the MBR membrane modules, and users can appropriately adjust the cleaning scheme and chemicals according to the pollutant composition.

- Optimize the process design and enhance the membrane system working environment, manufacturing construction, operation management, etc.

EcoLanTM focuses on developing and producing high-performance liquid separation membrane technology, with many product series such as microfiltration, ultrafiltration, and chemicals. We are committed to providing advanced liquid membrane treatment technologies and solutions to our global customers to promote the green regeneration and recycling of water resources.

Want More Information about Our Products & Solution?

Trustworthy Water Pollution Control Scheme Service Provider

Contact Information

- [email protected]

- +86 13670031794

- Room 314, Commercial Building 2, No.51 Fuyu East Road, Qiaonan Community, Panyu District, Guangzhou, China.

Copyright © 2022 Guangzhou EcoLan Environmental Technology Co., Ltd. | All Rights Reserved.

Privacy Policy

Welcome To Chat With Us!

Please scan the QR code in the figure below first. After adding WeChat friends, you can communicate online immediately