Nitrogen and Phosphorus Removal, 6 Combined MBR Technologies That Work

Table of Contents

Due to the wastewater discharge standards generally improving the requirements for nitrogen and phosphorus removal, almost all the traditional nitrogen and phosphorus removal processes have been applied to the MBR process, such as AO, A2O, SBR, etc., the technical problems encountered in these traditional processes will also be in the MBR nitrogen and phosphorus removal process. Still, some of the characteristics of the MBR process can play a reinforcing role in the original process. AO or A2O and its deformation enhancement process are the most outstanding treatment effects, the most convenient operation and management, and the most stable and verifiable category among the many applied MBR nitrogen and phosphorus removal processes.

Therefore, to achieve better wastewater purification, biochemical and MBR processes are often combined into a new composite process; the following will introduce a variety of forms of MBR nitrogen and phosphorus removal combined process.

How does an AO-MBR (Anoxic-Oxic MBR) system remove nitrogen and phosphorus?

AO process, also called the anaerobic (anoxic)-oxic biochemical treatment method, is a wastewater treatment process developed in the late 1970s, which not only removes BOD5 and COD from wastewater but also effectively removes nitrogen compounds from wastewater, featuring a simple process, less investment, and total nitrogen removal of more than 70%.

Section A tank is also known as an anoxic tank or hydrolysis tank. The mechanism of hydrolysis from the chemical point of view is that the vast majority of compounds in contact with water under certain conditions will be hydrolyzed; hydrolysis reaction can make covalent bonds change and break; that is, the compound in the molecular structure and morphology changes. The catalytic effect of biological enzymes accelerates biological hydrolysis, and the catalytic reaction speed under enzyme conditions is 108~1011 times higher than that under non-enzymatic conditions.

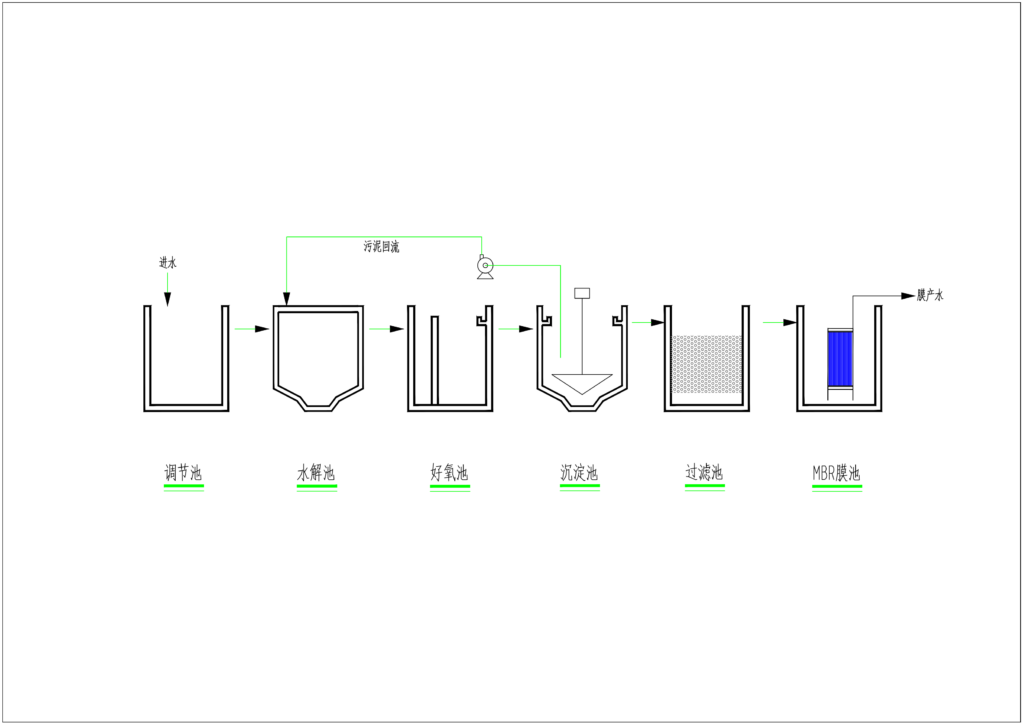

Biohydrolysis refers to the reaction that complex organic molecules are decomposed into simple compounds with the participation of hydrolases under anoxic conditions by adding water. It includes two processes: hydrolysis and acidification. Acidification can degrade organic matter into organic acids, enter the aerobic MBR membrane tank for aerobic biochemical action, and intercept activated sludge through membrane modules.

In the AO-MBR system, the wastewater separated from suspended solids and impurities flows into the regulating tank to balance the water quality and quantity. Then, it enters the sedimentation tank for solid-liquid separation. The supernatant flows into the MBR treatment tank, and the MBR treatment tank is designed as an AO system. The inflow water is thoroughly mixed in the front section for biological denitrification, and biodegradation and nitrification are performed at the back end. At the same time, alkali is added, and the effluent can be directly discharged or reused.

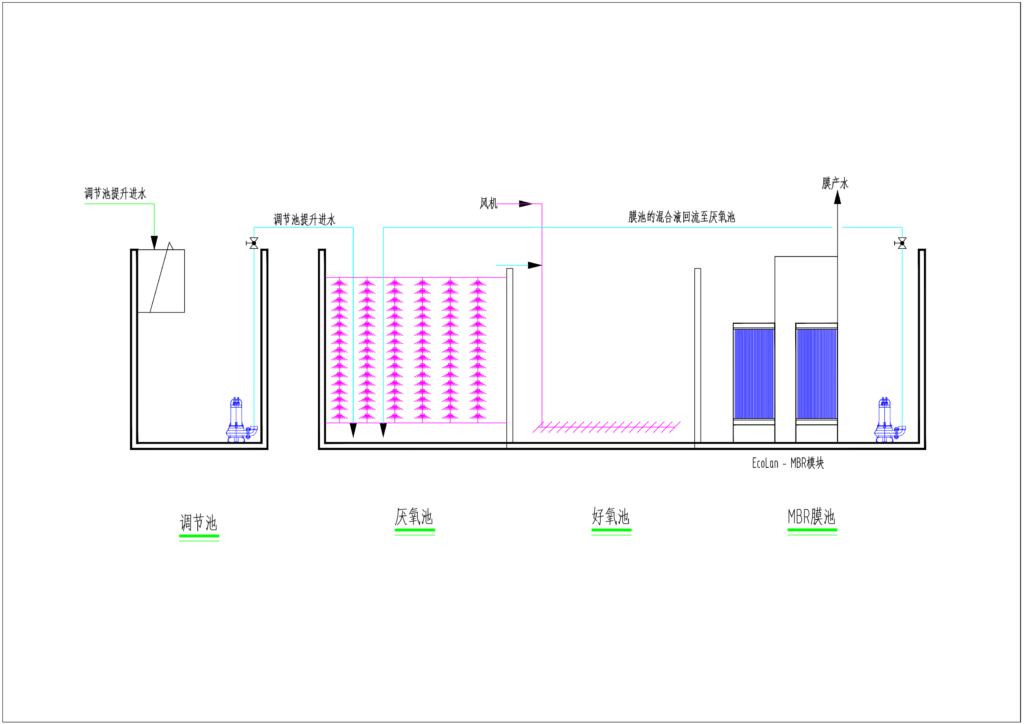

How does an A2O-MBR (Anaerobic-Anoxic-Oxic MBR) system remove nitrogen and phosphorus?

A2O is another phosphorus and nitrogen removal process based on the characteristics of microorganisms. A2O is an A-A-O, anaerobic-anoxic-aerobic process consisting of an anaerobic, an anoxic, and an aerobic tank in series.

The traditional biological nitrogen removal process usually uses pre-denitrification or post-denitrification to achieve nitrogen removal. In contrast, the A2O process with anaerobic, anoxic, and aerobic reactors can simultaneously remove carbon nitrogen and phosphorus. The A2O-MBR process with simultaneous nitrogen and phosphorus removal, which combines the A2O process and membrane separation technology, can further expand the application scope of MBR.

In this process, there are two stages of reflux. One is that the mixed liquid of the membrane tank is refluxed to the anoxic tank to achieve denitrification, and the other is that the mixed liquid of the anoxic tank is refluxed to the anaerobic tank to perform anaerobic phosphorus removal. The premise of denitrification is that NO3-H should be completely nitrated. The aerobic tank can complete this process. And the anaerobic tank can complete the task of denitrification. The anaerobic and aerobic tanks complete the phosphorus removal together.

The anaerobic tank in the first section mainly releases phosphorus so that the phosphorus concentration in the wastewater increases, the dissolved organic matter is absorbed by the microbial cells so that the BOD5 concentration in the wastewater decreases, and the synthesis of the cells removes the NH3-N. The concentration of NH3-N in the wastewater decreased, but the content did not change.

In the anoxic tank, the denitrifying bacteria use the organic matter in the wastewater as a carbon source to reduce the large amount of NO3-N and NO2-N introduced into the reflux mixture to N2 and release it into the air. Therefore, the BOD5 concentration continues to decrease, and the NO3-N concentration also decreases significantly, but the change in phosphorus is minimal.

In the aerobic tank, organic matter was degraded by microorganisms and further decreased; organic nitrogen was ammoniated and then nitrated, so the concentration of NH3-N decreased significantly, but with the nitrification process, the concentration of NO3-N increased, and phosphorus decreased rapidly with the excessive uptake of phosphorus accumulating bacteria.

The high concentration of MLSS, independently controlled hydraulic retention time and sludge retention time, reflux ratio, and sludge loading rate in the A2O-MBR process will have different effects from the traditional A2O process and have better nitrogen and phosphorus removal effects.

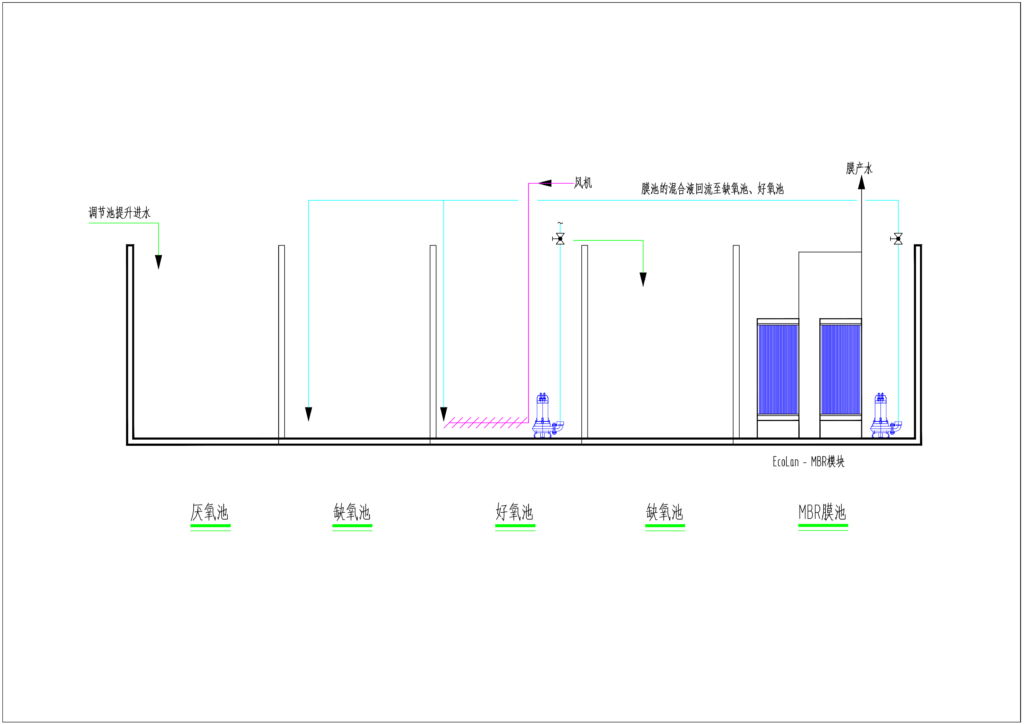

How does an A2O/A-MBR (Anaerobic-Anoxic-Oxic-Anoxic MBR) system remove nitrogen and phosphorus?

The A2O / A-MBR process is a new process to strengthen endogenous denitrification. The method uses high-concentration activated sludge and biodiversity in the MBR tank to enhance the effect of nitrogen and phosphorus removal. The process flow is anaerobic, anoxic, aerobic, anoxic, and MBR membrane tank. In this process, an extra anoxic tank was set up after the normal A2O process. After biological phosphorus and nitrogen removal were completed using the influent carbon source, the second anoxic tank was used for endogenous denitrification to remove TN further. Finally, aerobic aeration of the membrane tank was used to ensure effluent quality.

The A2O / A-MBR process is designed for wastewater treatment projects with insufficient influent carbon sources and high nitrogen removal requirements. It is also an enhanced version of the A2O-MBR nitrogen and phosphorus removal process.

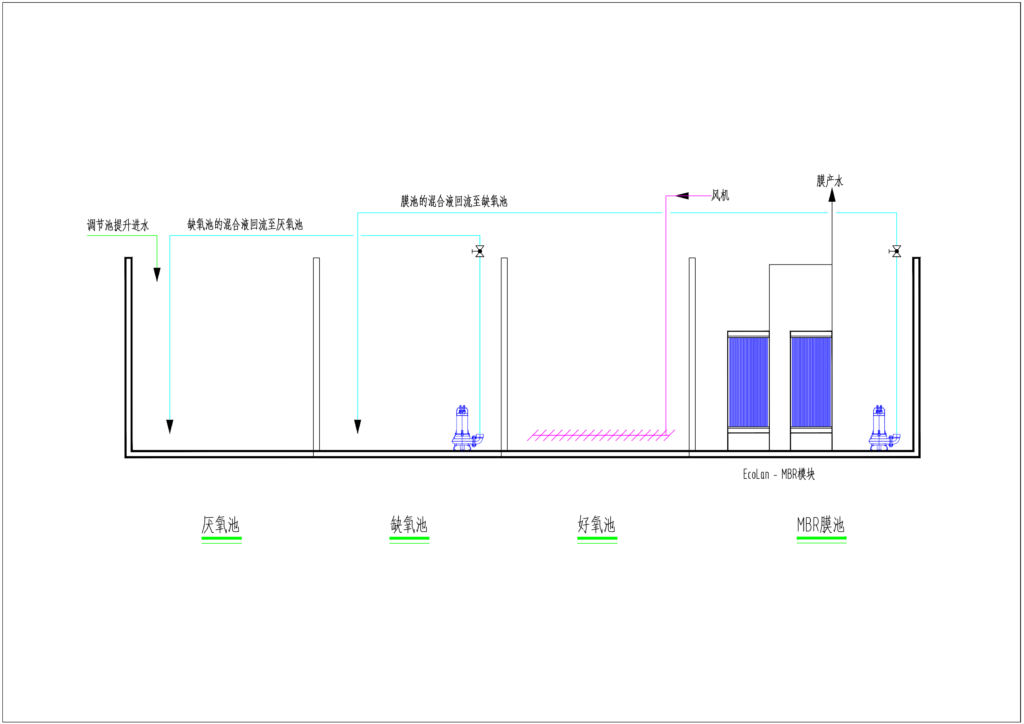

How does the 3A-MBR (Anoxic-Anaerobic-Anoxic-Oxic MBR) system remove nitrogen and phosphorus?

3A-MBR is a new type of wastewater treatment process with high efficiency of nitrogen and phosphorus removal, which is based on the mechanism of biological nitrogen and phosphorus removal and combined with the characteristics of membrane bioreactor technology. The basic principle is that the high concentration of nitrification liquid and activated sludge in the membrane bioreactor creates good anoxic and anaerobic conditions through the reflux system to achieve efficient nitrogen and phosphorus removal in the system.

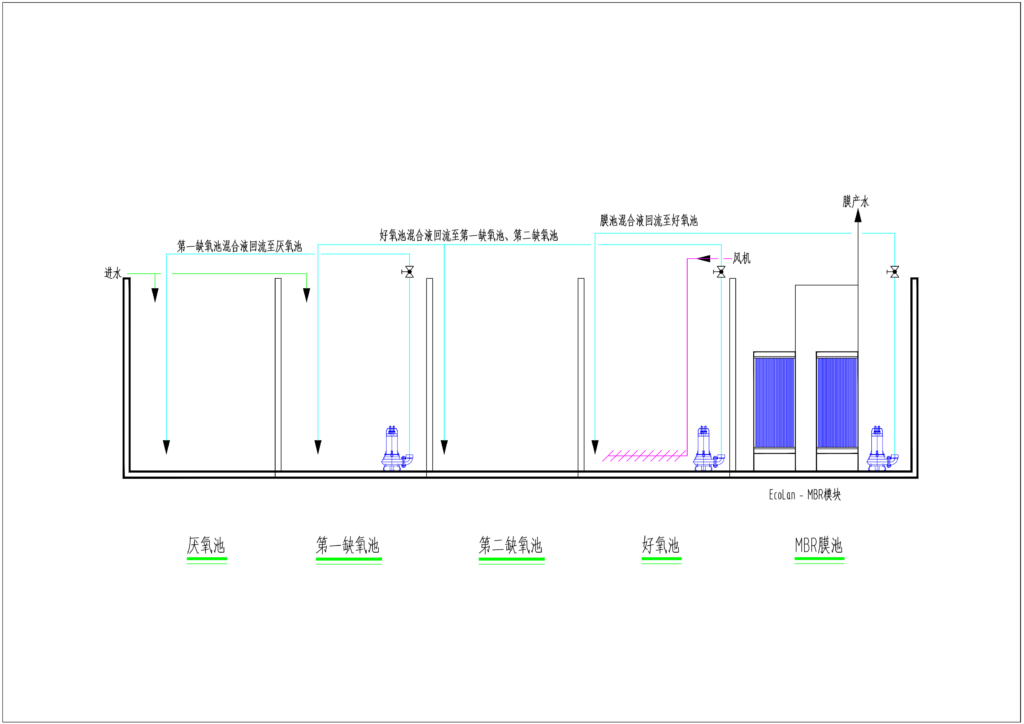

The internal flow of the process is first anoxic tank, then anaerobic tank, second anoxic tank, aerobic tank, and membrane tank, in order. The mixture of the membrane tank is refluxed to the first anoxic tank and the second anoxic tank, respectively. The first anoxic tank uses the influent carbon source and refluxed nitrification liquid for rapid denitrification. Then, the mixture enters the anaerobic tank for anaerobic phosphorus release, which reduces the effect of nitrate on phosphorus release. The second anoxic tank recycles the remaining carbon source and reflux nitrification liquid into the effluent for further denitrification. In the aerobic tank, various reactions, such as organic matter degradation, aerobic phosphorus absorption, and aerobic nitrification, occur simultaneously, and the pollutants in the wastewater are entirely removed. The mixture is filtered through the MBR membrane to remove organic matter, nitrogen, and phosphorus from the wastewater.

At the same time, fully increase the high concentration of activated sludge in the MBR membrane reaction tank, promote the formation of dominant nitrifying bacteria community, and improve nitrification efficiency so that ammonia and nitrogen removal is complete. Through automatic control, optimize the time of membrane bioreactor sludge discharge, reasonably control the age of sludge, increase the concentration of slow-growing nitrifying bacteria, denitrifying bacteria, and other specialized biochemical bacteria in the system, and improve the effect of organic matter and phosphorus removal and denitrification; Realize aerobic sludge discharge, avoid secondary release of phosphorus, and enhance phosphorus removal rate.

The 3A-MBR process reasonably combines various treatment units such as organic matter degradation and nitrogen and phosphorus removal, coordinates the functions of various biodegradation, achieves the purpose of simultaneous removal of various pollution indicators, and maximizes the efficiency of phosphorus and nitrogen removal and organic matter removal in the whole system, which has high application value.

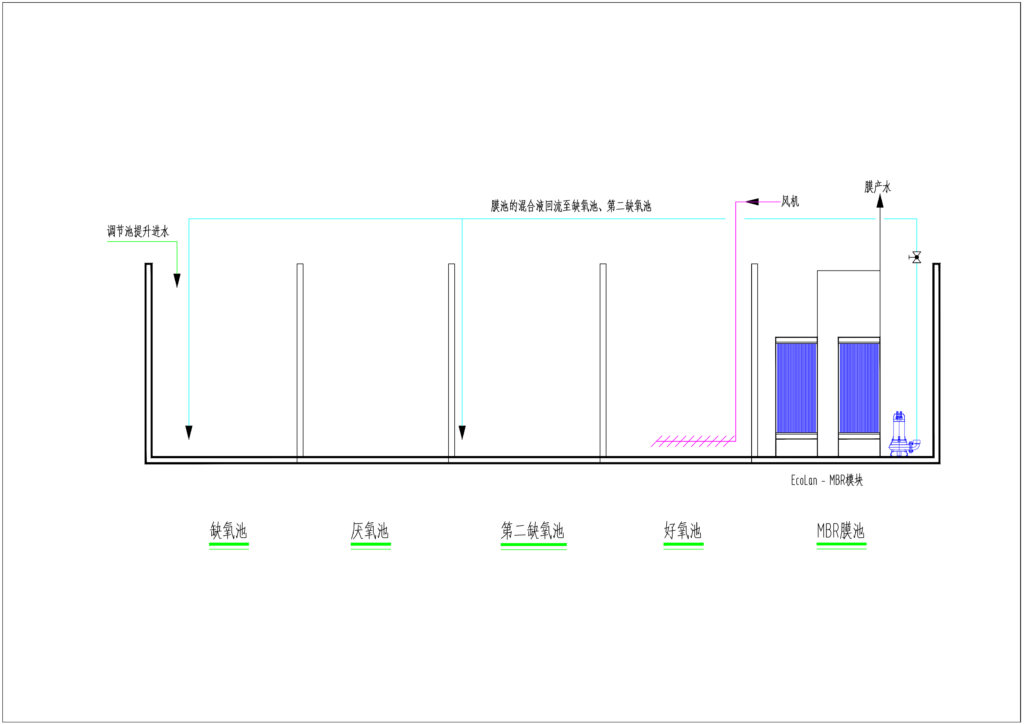

How does an A(2A)O-MBR (Anaerobic-Anoxic-Anoxic-Oxic MBR) process remove nitrogen and phosphorus?

The process flow of A ( 2A ) O-MBR process is an anaerobic tank, first anoxic tank, second anoxic tank, aerobic tank, and membrane tank in order. It is characterized by setting up two anoxic zones in the A2O-MBR process and adjusting the function of the anoxic zones at both ends by controlling the influent and reflux points. The water inflow method adopts two points of the anaerobic tank and the first anoxic tank, and the reflux method adopts three-stage two-point reflux. The first stage is the MBR membrane tank mixed liquid reflux to the front end of the aerobic tank, the second stage is the aerobic tank mixed liquid reflux to the first anoxic tank and the second anoxic tank, respectively, and the third stage is the mixed liquid of the first anoxic tank flow to the anaerobic tank.

There are three general types of carbon sources used for biological denitrification: raw water carbon sources, external carbon sources, and endogenous carbon sources. Biological denitrification requires organic carbon sources as electron donors for energy production and cell synthesis. The pre-denitrification process using the raw water carbon source generally has a low total nitrogen removal rate. If the nitrogen removal efficiency is to be further improved, an additional carbon source is required for denitrification.

Studies have shown that carbohydrates (50.2%), proteins (26.7%), and fats (20.0%) in sewage sludge are slow biodegradable carbon sources. By converting these substances into readily biodegradable carbon sources for denitrification systems, wastewater’s biological nitrogen removal efficiency can be significantly improved while avoiding additional carbon sources and saving operating costs. The design of the two-stage anoxic zone of the A(2A)O-MBR process is based on this principle. In the first anoxic tank, the NO3 refluxed from the aerobic tank is reduced to achieve complete denitrification, while in the second anoxic tank, endogenous denitrification is reached, saving the addition of external carbon sources, so it has high application value.

How does the SBR-MBR (Sequencing Batch Reactor MBR) process remove nitrogen and phosphorus?

The SBR-MBR process is a new process combining SBR and MBR; in addition to the advantages of general MBR, it is helpful to the operation of the MBR membrane module and the SBR process. SBR (Sequencing Batch Reactor) is an improved activated sludge treatment process, mainly characterized by its sequencing and intermittent operation. It alternately uses the time series’s intermittent or limited aeration operation mode to achieve an anoxic and aerobic process.

Due to the interception and filtration effect of the MBR membrane module, the microorganisms in the reaction can grow to the maximum extent, which is conducive to the growth and reproduction of nitrifying and nitrite bacteria with a long generation cycle. Therefore, the sludge has high biological activity, a solid ability to adsorb and degrade organic matter, and a good nitrification ability. At the same time, the sequencing batch operation mode can also delay the MBR membrane fouling.

The process integrates influent, anaerobic, aerobic, and sedimentation in one tank, which not only provides conditions for the growth of phosphorus-removing bacteria and meets the needs of nitrogen removal but also makes it possible to achieve simultaneous high-efficiency removal of nitrogen, phosphorus, and organic matter in a single reactor. It can also flexibly change the operation mode to meet the treatment requirements of different wastewaters, which is convenient for automatic control. Compared with the traditional SBR system, SBR-MBR utilizes an MBR membrane to separate effluent in the reaction stage, improving wastewater purification efficiency and saving time.

The following aspects should be considered when designing MBR processes for nitrogen and phosphorus removal (including MBR processes for nitrogen removal).

- The aerobic tank is the basis of the whole process, according to the characteristics of influent water quality, effluent water quality requirements, and other factors to determine the optimal proportional relationship between the residence time of the anaerobic zone, the residence time of the anoxic zone and the residence time of the aerobic zone, to determine the size of the anaerobic tank, anoxic tank, and aerobic tank.

- The characteristics of the influent, especially the biodegradability of the wastewater, the nitrogen-carbon ratio, the phosphorus-carbon ratio, and other factors, have an important influence on the design of the process parameters and require special attention.

- The proportion of sludge in the non-aerobic zone (anaerobic and anoxic zones) to the total sludge is generally at most 50%, i.e., the tank capacity in the aerobic area is usually larger than the sum of the tank capacity in the anaerobic and anoxic zones.

- The shorter sludge retention time is generally beneficial for phosphorus removal. Still, the sludge retention time in the MBR process is generally longer, which hurts biological phosphorus removal and often requires the cooperation of chemical phosphorus removal methods.

- Alkalinity is an essential guarantee for the stable operation of the whole MBR process, and the process design needs to consider the balance and stability of alkalinity in the entire process.