EcoLanTM MBR Membrane Module Replacement Case

Project Overview

Project name: A mine bathing wastewater treatment project

Number of MBR membrane elements: 80pcs EcoLan TM EL M-5080

Water production capacity: 750m3/day

MBR module replacement date: June 2022

System process flow: Mine bathing wastewater → Regulating tank → Anaerobic tank → Aerobic tank → EcoLan MBR tank → Clear water tank → Effluent reuse

Produced water quality: turbidity ≤ 1NTU, TSS ≤ 10mg/L

Design feed water quality

The feed water of the MBR system is the product water of the pretreatment unit, and the following criteria need to be met.

| Number | Control index | Maximum limit |

| 1 | pH value | ≤10 |

| 2 | COD | ≤1000mg/L |

| 3 | BOD | ≥120mg/L |

| 4 | TSS | ≤100mg/L |

| 5 | TDS | 600~5000mg/L |

| 6 | NH3-N | ≤35mg/L |

| 7 | Hardness | ≤600mg/L |

EcoLan’s membrane module specifications and technical parameters

To maintain the regular and stable operation of the MBR system, we developed the following plan to replace the MBR membrane module with a treatment capacity of 750 m³/day, based on a preliminary understanding of the industrial wastewater quality of this project.

| Number | Item Name | Technical Specifications | Remark |

| 1 | Treating water | Mine bathing wastewater | |

| 2 | Capacity | 750m³/day | |

| 3 | Designed flux | 15L/(㎡·h) | Instantaneous flux(25℃) |

| 4 | Design effluent quality | Level 1A(GB18918-2002) | Requires normal pretreatment |

| 5 | MBR membrane | Curtain hollow fiber membrane | |

| 6 | Membrane material | PVDF + PET | |

| 7 | Pore size | 0.1μm | |

| 8 | Filament inner/outer diameter | 1.5/2.6mm | |

| 9 | Filtration accuracy | 0.1μm | |

| 10 | Filtration mode | Submerged suction filtration (Out to In) | |

| 11 | Expected life | ≥2 years | |

| 12 | Tensile strength | ≥200N | |

| 13 | Max pH value | 2~12 | |

| 14 | Tolerable residual chlorine concentration | 3000ppm | |

| 15 | Oil content requirement | ||

| Mineral oil: ≤3mg | |||

| 16 | Sealing material | polyurethane adhesive | |

| 17 | Active membrane area | 34m2/pc | |

| 18 | Membrane size | 1250*30*2000mm | |

| 19 | Quantity | 80pcs |

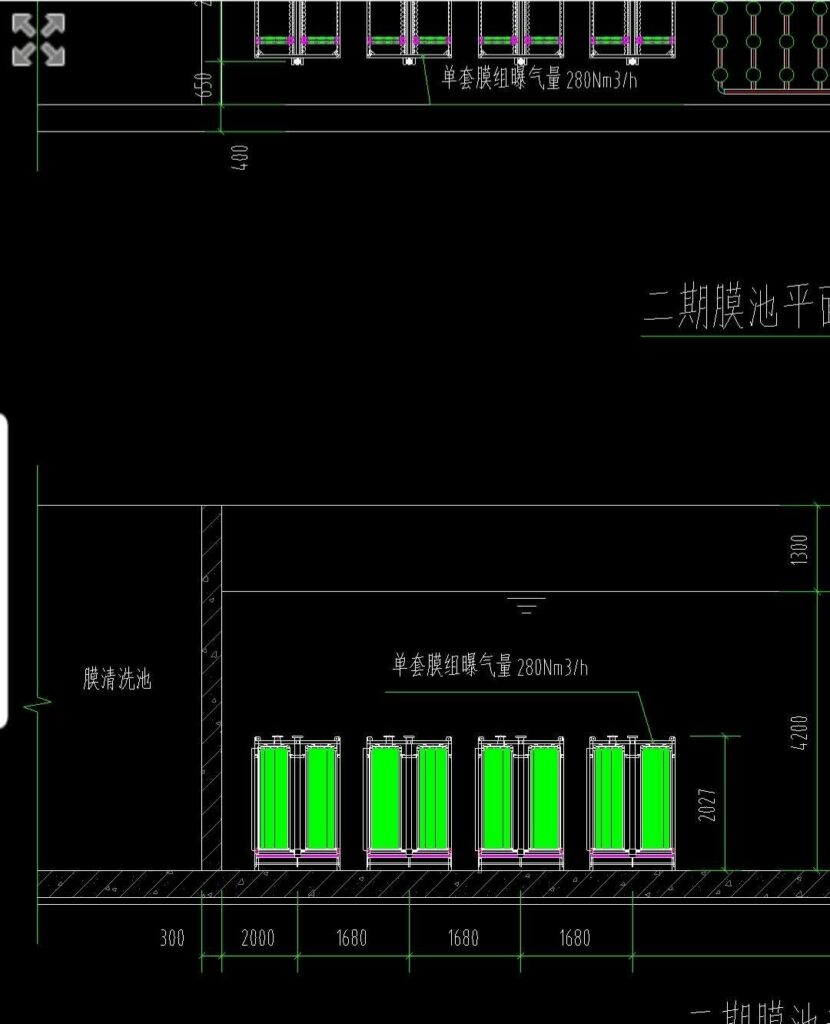

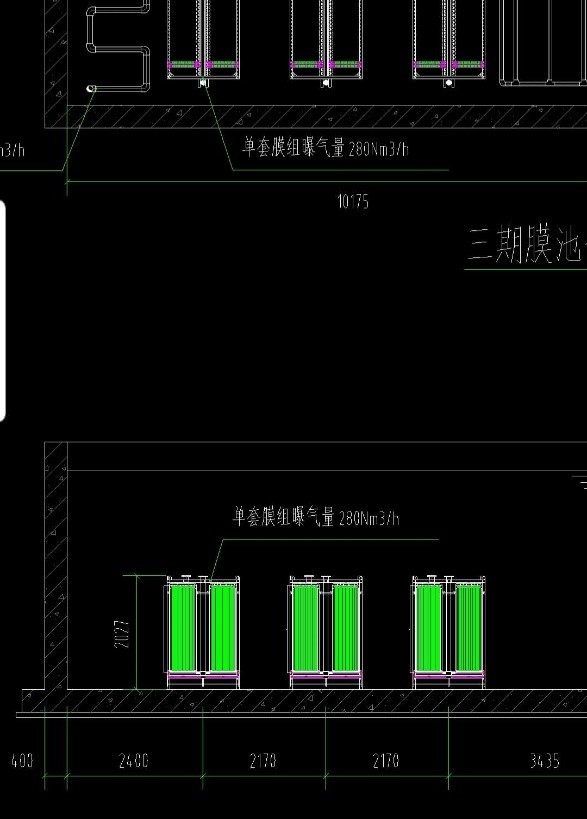

Phase II and Phase III membrane modules are 2200mm and 2520mm long, 1680mm and 2170mm in width, and 2027mm in height, based on the project’s existing membrane modules. See the below chart for details.

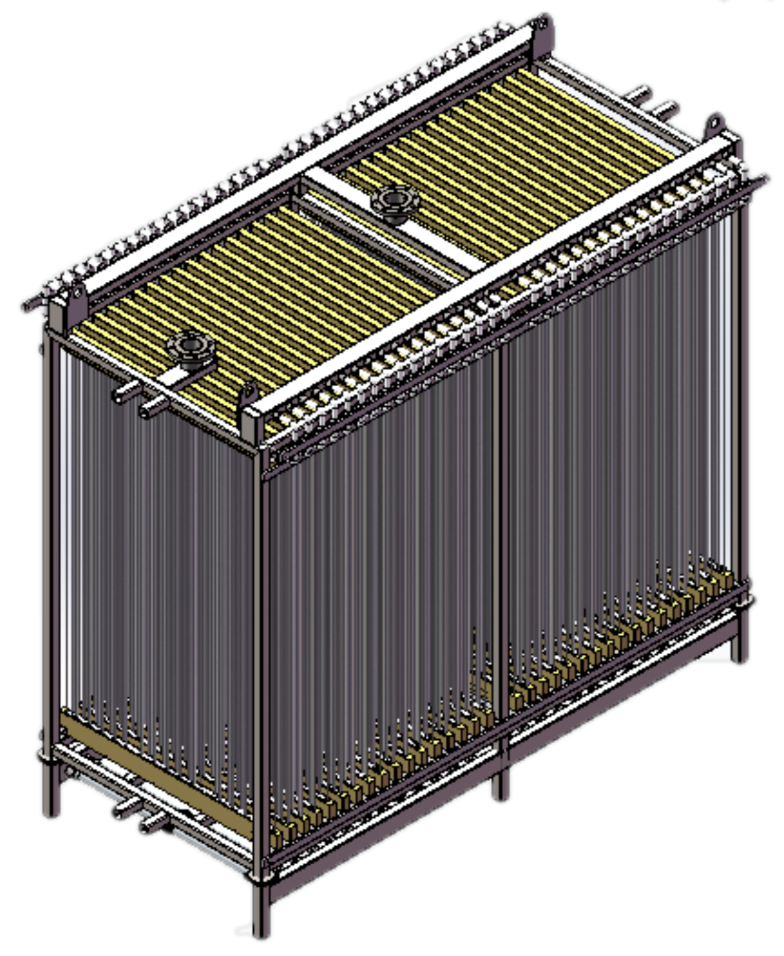

Two EcoLan membrane modules of 2520 x 1500 x 2700 mm are proposed to be replaced to fit the available space in the on-site membrane tank. It will allow the production of 750 m³/day for more than two years. A diagram of the new MBR modules is shown in the figure below.

The membrane module is easy to install and remove, the hollow fiber membrane sheet does not break or peel, the flux is stable, and it can withstand high-pressure water backwash. The recommended backwash pump flow rate is 75.6 m³/h, the aeration blower volume is 7.5 m³/min, and the system online cleaning pump flow rate is 10.08 m³/h.

MBR membrane module operating conditions

| Item | Unit | Parameters |

| PH value | / | 6-9 |

| Working temperature | ℃ | 5-35 |

| Mineral oil content | mg/l | <3 |

| TMP | Mpa | -0.01 ~ -0.05 |

| Backwashing pressure | Mpa | ≤ 0.2 |

| MLSS | mg/l | 4000-12000 |

| Operating mode | / | Filtration 8~12min, stop 1~2min |

| Aeration | Air-to-water volume ratio | (10~15):1 |

Cleaning of MBR membrane modules

Option A

| Water backwashing | |||

| Chemicals for cleaning | Concentration | Cleaning frequency | Cleaning duration |

| Clear water or product water | 1 to 2 times water production | 4~6 times a day | 1~5 minutes (per series), backwash pressure: 0.05 to 0.2Mpa, max. not exceeding 0.5Mpa |

| CIP (Clean in place) | |||

| Chemicals for cleaning | Concentration | Cleaning frequency | Cleaning duration |

| NaClO | 100-500ppm | Every 1-3 months of running | 60 minutes((per series) |

| Citric acid, HCl | 0.1-0.2% | Every 1-3 months of running | 60 minutes((per series) |

| COP (Clean out of place) | |||

| Chemicals for cleaning | Concentration | Cleaning frequency | Cleaning duration |

| NaClO | 1000-2000mg/L | 1 time in 5~6 months | 8~12 hours((per series) |

| NaOH and Oxidizing agents | NaOH: 0.1mol/L~0.5mol/L,Oxidizing agents : 200 mg/L | 1 time in 5~6 months | 8~12 hours((per series) |

| Citric acid | 1-3% | 1 time per half-year | 8~12 hours((per series) |

Note:

① COP cleaning is only considered when TMP cannot be restored by CIP cleaning, which can be done once in 3 months to once a year. According to the high hardness of the incoming water, which is prone to scaling situations, we propose adjusting the frequency and concentration of acid cleaning according to the actual condition.

②After chemical cleaning, it should be rinsed with water sufficiently before use. It is necessary to rinse with water between changing chemicals when using multiple chemicals for cleaning.

Option B

| Maintenance cleaning (low-concentration fluid cleaning) | |||

| Chemicals for cleaning | Concentration | Cleaning frequency | Cleaning duration |

| NaClO | 300-500mg/L | 1-2 times per week | 60 minutes((per series) |

| Recovery cleaning (high-concentration liquid cleaning) | |||

| Chemicals for cleaning | Concentration | Cleaning frequency | Cleaning duration |

| NaClO | 1000mg/L | 1-2 times per month | 60~90 minutes((per series) |

| Citric acid | 0.5-1% | 1-2 times per month | 60~90 minutes((per series) |

| Soak clearing | |||

| Chemicals for cleaning | Concentration | Cleaning frequency | Cleaning duration |

| NaClO | 1000-2000mg/L | 1~2 times per year | 8~12 hours((per series) |

| NaOH and Oxidizing agents | NaOH: 0.1mol/L~0.5mol/L,Oxidizing agents : 200 mg/L | 1 time in 5~6 months | 8~12 hours((per series) |

| Citric acid | 1-2% | 1~2 times per year | 8~12 hours((per series) |

MBR System Operation and Maintenance

To ensure the stable and regular operation of the MBR system, the customer must do the following in the operation process.

- Ensure high activated sludge and reasonable sludge concentration from 4000 mg/L to 12000mg/L. There cannot be no activated sludge or activated sludge concentration below 4000mg/L. The MBR membrane is more likely to be fouled if there is no activated sludge or low activated sludge concentration in the MBR membrane tank. Meanwhile, the better the activated sludge activity, the better for MBR system operation.

- Ensure that the MBR system operates automatically with regular backwashing and online maintenance chemical cleaning, as well as offline cleaning once or twice a year, depending on the situation.

- Once in operation, the MBR membrane must not be exposed to sunlight or ice as this will result in irreversible loss of MBR membrane flux or even scrap.

- The feed water of the MBR membrane tank must not contain fibrous, debris flakes, and other substances that damage the membrane filaments, such as fibrous flakes and hair.

- The feed water of the MBR membrane tank should be reduced as much as possible to the membrane-damaging solvents, flocculants, and other substances such as DMF, polymeric alcohols, PAM, etc. At the same time, wastewater without activated sludge treatment should not be directly treated by the membrane.